1 Overview

ShitongTM high-precision dynamic optical wavefront measuring instrument is widely used in optical component surface measurement, optical system assembly, aerospace, laser parameter diagnosis, high-end equipment manufacturing, biomedical and other fields.

Dynamic optical surface measuring instrument in kind

Dynamic optical surface measuring instrument (with objective lens)

The dynamic optical surface gauge is equipped with a standard objective lens

2 Features

1) It has wavefront distortion PV, RMS, zernike aberration coefficient/lengder aberration coefficient, Strel ratio (SR), point spread function (PSF), line spread function (LSF), modulation transfer function (MTF) measurement function module;

2) Real-time dynamic measurement and multiple average measurement, relative measurement and absolute measurement;

3) Manual and automatic setting of measurement mask (mask);

4) Non-uniform light field wavefront measurement;

5) frequency response characteristics close to unit uniform response;

6) The working wavelength can be extended to the extreme ultraviolet-infrared spectroscopy measurement range;

3 Unique technology

SeeToneTM high-precision dynamic optical wavefront measuring instrument adopts RTCCD patented technology, which includes frequency response optimization wavefront reconstruction technology (Reconstruction), system thermal control technology (Thermal), high-precision coupling (Coupling), ultra-high-precision error calibration (Calibration), high-speed integrated wavefront detection technology (Detect), and the measurement system developed based on the above technology realizes high-precision and high-precision in the visible and infrared bands. Applications in the field of dynamic surface shape measurement.

The main features are: 1) no requirement for light field coherence, no need for reference light; 2) Good real-time performance, up to 50 frames/second; 3) Large dynamic range, measurement dynamic range from micron to nanometer; 4) Strong anti-interference ability, reliable test data can be obtained under strong airflow disturbance and vibration conditions.

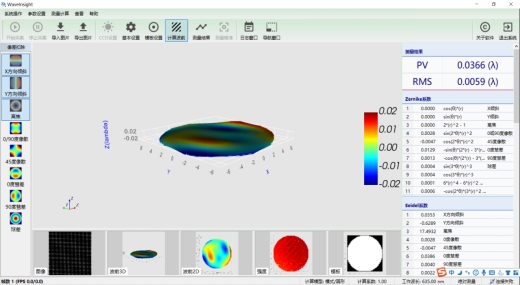

4 WaveInsight Pro? metrology software

WaveInsight Pro? metrology and analysis software is used for dynamic and visual display of the measuring instrument, and the patented acquisition algorithm is perfectly combined with the hardware of the measuring instrument to meet the measurement and analysis needs, and the software interface is friendly and easy to operate.

The software has the functions of real-time calculation and display of wavefront 3D distribution, zernike aberration coefficient, Seidel aberration coefficient, Strelby, point spread function and MTF, and can be expanded according to customer needs.

Wavefront measurement analysis software

5 Hardware Configuration

The VisionTM High Precision Dynamic Optical Wavefront Meter comes with two sets of standard optical lenses to meet most optical testing needs. At the same time, we can provide professional services according to customer needs, and tailor test lenses for you to meet different application scenarios.

6 models and parameters

Model | HSWS-VIR-128 Sharp Sight | HSWS-VIR-512 Finesight | HSWS-SWIR-128 Boshi |

Operating wavelength | 400nm-1100nm | 400nm-1100nm | 1100nm-1700nm |

Absolute Measurement Accuracy (RMS) | <0.01λ@635nm | <0.01λ@635nm | <0.01λ@1550nm |

Measure sensitivity | ~1nm | ~1nm | ~5nm |

Measure dynamic range | ≥300λ@635nm | ≥100λ@635nm | ≥100λ@1550nm |

Measure the frame rate | 20 frames/sec | 20 frames/sec | 50 frames/sec |

Sampling points | 128X128 | 512X512 | 160X128 |

Wavefront measurement analysis software | Operating system: Windows 10 Self-developed metrology and analysis software | Operating system: Windows 10 Self-developed metrology and analysis software | Operating system: Windows 10 Self-developed metrology and analysis software |

Working environment | Humidity 20%~70%; Temperature: 15°C~30°C | Humidity 20%~70%; Temperature: 15°C~30°C | Humidity 20%~70%; Temperature: 15°C~30°C |

Features: | Optical workshop, precision manufacturing main model The SharpVisionTM gauge quickly and reliably measures surface shape errors and transmitted wavefronts of optical components, optical systems, and optical assemblies. Achieve accurate measurements from a stable, interference-free, high-quality laboratory environment to a complex environment with frequent vibrations and strong air turbulences. It's versatile and flexible enough to meet demands ranging from high-end telescope testing to real-time phase feedback on actively aligned optical systems. |

The GeTVTM meter has an extremely high spatial resolution. The rigorous optical design ensures the pixel-limited performance of the meter and captures the surface details required for the most demanding applications. | 适用于高精度红外成像应用的测量 BoshiTM measuring instrument has the characteristics of high resolution and fast response in the infrared band. Different from visible light measurement systems, infrared systems with different requirements for wavelengths also need to be precisely measured, such as in aerospace night vision, infrared and thermal imaging systems, lithography subsystems, remote sensing telescopes and material identification and other fields, the use of Broadview TM measuring instrument can obtain more accurate measurement data |

Lead time | 45-60 days | 45-60 days | 60-90 days |

Maintenance services | The product is guaranteed for one year; Provide 3 free on-site testing services within one year | The product is guaranteed for one year; Provide 6 free on-site testing services within one year | The product is guaranteed for one year; Provide 6 free on-site testing services within one year |